Initially, you might be perplexed if you hear the word “bellows” in relation to boats. Flexible gaskets called bellows to keep the engine of your boat dry. To avoid rusting and other problems, they have a watertight seal.

We’ll talk about the various kinds of bellows and how they operate in this blog post. We’ll also give you some advice on how to keep your bellows system in good working order.

What Are Bellows On A Boat?

Perhaps the first thing that comes to mind when you hear the word bellows is an apparatus for igniting a fire and moving air. The sides’ accordion shape serves as the only point of connection. It describes a flexible gasket used on boats to shield some engine components from moisture.

Usually, it is strengthened for increased strength and clamped into position for a watertight seal.

Instead of a closed system like an automobile, most vessels have an open water cooling system. They use water to keep the craft at a safe temperature by dissipating heat produced by the engine instead of antifreeze and a radiator.

Some components are vulnerable to damage if they get wet because there is water in the unit. You’ll have to look at new boat prices if that occurs.

Types Of Bellows

Different types of bellows on a boat are:

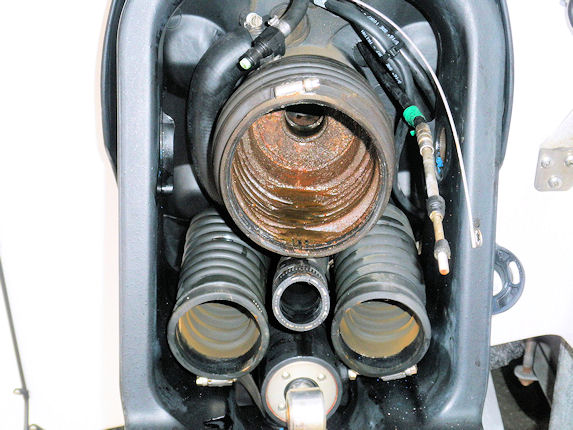

U Joint Bellows

The driveshaft’s end contains the U joint bellows. They assist in preventing water and debris from getting into the engine and transmission. A small amount of movement is permitted by U-jointed bellows, which lessens vibration.

Exhaust Bellows

Between the boat’s hull and the exhaust manifold are where the exhaust bellows are situated. They assist in keeping dirt, water, and other objects out of the engine compartment. Additionally, a little movement is permitted by the bellows, which lessens vibration.

What Do Bellows Do?

Bellows can be used for a variety of purposes, such as:

Inflating Life Jackets Or Mattresses

Use bellows to blow up any inflatable items you may have, such as a mattress or life jacket. Simply fasten the bellows to the valve and blow air into the apparatus.

Pumping Water Out Of The Boat

A bilge pump can be used to drain the water from your boat if it starts to take on water. Bilge pumps can be run on electricity or a manual hand pump. The hose’s other end should be submerged in water as you attach the bilge pump to it.

The water from your boat will begin to drain once you turn on the pump.

Starting A Fire

Bellows can be used to produce a spark in order to start a fire. The air will be pumped into the chamber after the bellows are placed over the fire pit. This will produce a spark that can be used to start the fire.

Powering A Forge

Forges can also be run on bellows. Metals are heated in forges so they can be formed. In order to maintain a hot fire, the bellows pump air into the forge.

Ventilating The Cabin

Exhaust bellows are also frequently utilized on sailboats to ventilate the cabin. In addition to keeping the air clean, this prevents the accumulation of hazardous gases like carbon monoxide.

Communication

The exhaust bellows can occasionally be used to convey information. For instance, on whaleboats and fishing boats, a loud blast from the bellows can be used to signal for assistance or warn other boats of danger.

Fumes And Exhaust

Bellows aid in preventing the accumulation of exhaust and fumes inside the boat. For both comfort and safety, this is critical. Make sure to check the bellows in any boat you ever ride in with an engine to make sure they are in good working order.

The Benefits Of Using Bellows On A Boat

There are many benefits of using bellows on a boat such as:

Help To Prevent Water Damage

Bellows can aid in limiting the effects of water. The added pressure from the expanding bellows can aid in containing a leak if a boat begins to absorb water.

Additionally, any water that has already entered the boat can be pumped out using the bellows. This can lessen the likelihood that the boat will sink or sustain water damage.

Help To Ventilate A Boat

A boat can also be ventilated using bellows. A boat’s interior air can become stale and develop condensation on the walls and ceiling if it is shut up for a long time. You can help avoid this from happening by using bellows to circulate the air.

Furthermore, moving the air around the boat can aid in preventing the growth of mold and mildew.

Help To Extend The Life Of Your Boat

Bellows can also contribute to the longevity of your boat. Your boat can avoid developing a permanent deformity if you regularly inflate and deflate it with bellows.

What Materials Are Possible For Bellows?

What materials are possible for the bellows? Metal bellows, in particular, can be made from a variety of metal alloys, such as brass, bronze, nickel, Monel, beryllium copper, and stainless steel. The best material to use in marine environments is typically stainless steel. It does not rust, which is the main explanation.

In order to prevent rusting, bellows made of stainless steel typically contain a standard ratio of iron, carbon, chromium, and nickel. For steel, the iron and oxygen mixture that typically causes rust is incapable of resisting one another and bonding to form a surface film of iron oxide, so it cannot rust.

Additionally, Marine Grade Stainless Steel alloys typically contain molybdenum, an element with the atomic symbol 42 and a melting point of 4,748 degrees Fahrenheit, to resist the corrosive effects of salt in marine environments.

How Are Bellows Used On A Boat?

- Before using a bellows, confirm that the valve is open.

- Put the bellows over the hole you want to use to pump water out of.

- Sharply exhale while placing your mouth over the top of the bellows. As a result, a vacuum will be created, drawing the water up into the bellows.

- When the bellows are full, take them out of the hole and set them over the final compartment.

- Additionally, you can adjust the valve to regulate the water flow by using the bellows expander tool to tighten or loosen it.

How To Know If Your Bellows Are Bad?

If there is water in your cabin, there is probably a crack in your boat (or possibly a loose gasket or clamp), which makes it very easy to determine whether your bellows are malfunctioning. It may also be a sign of trouble if there is a loud noise while driving. It might indicate problems with the U-joint bellows or the gimble bearing.

If you experience any shifting problems, the gimble bearing or the U-joint bellows are probably to blame. The exhaust bellow on your boat is malfunctioning if it overheats.

Identifying a problem with your bellows can be crucial because if it worsens, you may need to replace the entire boat. This would require a great deal of your time, be extremely expensive, and almost certainly result in some stress for you. Therefore, it’s crucial to keep an eye out for potential problems that could result from routine boat maintenance.

How Should The Boat Bellows Be Replaced?

Any of these parts usually requires an expensive repair. The mechanic must take the lower unit apart in order to access the bellows, which takes time and effort. Although it isn’t difficult, you will need assistance. It is a task for the skilled do-it-yourselfer.

You’ll require specialized equipment, some of which you can rent at your neighborhood auto parts shop. If you use them, you should expect to pay less than $100.

Ideally, all of the bellows should be replaced simultaneously. They have experienced a similar level of wear, after all. Drying out of the rubber is the root of the issue. They deteriorate with regular use. You might as well do it since you’ll be turning off the lower unit anyhow.

It’s not outrageous with the parts. For less than $50, you can purchase a shift cable bellows. The price for the other two will be about $100. For your particular boat’s make and model, you’ll need adhesive and lubricants. Ironically, after spending several hours on the drive, it only takes less than 30 minutes to replace them.

Replacing Exhaust Bellows

You need to uncinch the clamps on both ends of the exhaust bellows. To clean the forward mount, first, you should remove the old bellows.

To replace this component in the housing, reinstall the clamp in the adhesive and use a bellows expander tool. The front clamp should then be replaced, and all of the screws should be facing downward.

Replacing U-joint Bellows

This is similar to the one previously mentioned, except that the gasket and the O-rings need to be checked and replaced as well. The housing should also be examined for rust and debris, and if necessary, cleaned out. It can be expensive to purchase new housing, so maintaining existing housing is a good idea.

Additionally, the gimble bearing might need to be replaced.

Replacing Shift Cable Bellows

The shift cable bellows replacement process is simpler than the previous two. These parts are smaller and easier to handle than the first two, but the setup is essentially the same. Replace the bellows after removing the clamps and cleaning the housing. If you don’t do this properly, you might later run into more costly issues.

How Should Your Bellows Be Storied When Not In Use?

It’s critical to keep your bellows in a cool, dry environment when not in use. Additionally, a watertight seal ought to be used. Keep them in a dim area if at all possible because light can harm the leather. The best thing to do is to hang your bellows on a hook or nail, as this will help keep them from wrinkling.

In order to protect the leather, wrap your old bellows in a soft cloth before placing them in a drawer or cabinet. Your bellows will provide many years of enjoyment if you take good care of them.

How To Prevent Bellows Issues?

Once you’ve fixed it once, adding it to your list of annual maintenance tasks won’t be as difficult. The most important thing to keep in mind is that, if something goes wrong on the water, prevention is far simpler than having to tow the boat and have it repaired.

Examine other components, such as the water intake, in detail. Examine each gasket and O-ring, and replace any that need it. If the gimble bearing is still spinning freely, lubricate it. This additional layer of defense will prevent it from rusting.

Before replacing the drive, make sure the setup is aligned properly. A specialized tool is available to make sure everything is configured correctly.

Many of these tasks, thankfully, are simple to complete. Always keep in mind that the cost of repairs is primarily caused by the time required to reach these parts. If you’ve made it this far, check everything you can while the boat is out of the water and you are in the drive. You can spend more time boating if you put in the effort now.